Introduction to Constant-Velocity Joint:

A constant-velocity joint (CV joint) is a crucial component in the drivetrain of vehicles, particularly those with front-wheel drive, all-wheel drive, or four-wheel drive systems. CV joints play a vital role in transmitting torque from the engine to the wheels while accommodating the vehicle’s suspension movement and allowing for smooth and consistent power delivery, even during steering maneuvers. Understanding the function, types, and maintenance of CV joints is essential for ensuring optimal vehicle performance and longevity.

Function of CV Joints:

CV joints facilitate the transfer of torque from the transmission to the wheels while accommodating the articulation and movement of the vehicle’s suspension system. They allow for smooth and consistent power delivery to the wheels, even during steering and suspension movements, ensuring stable and predictable vehicle handling and performance.

Types of CV Joints:

There are several types of CV joints, including the Rzeppa joint, ball-type CV joint, and tripod joint. Each type has its unique design and configuration, but they all serve the same fundamental purpose of transmitting torque while accommodating articulation and movement in the drivetrain.

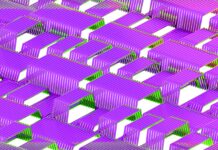

Components of CV Joints:

CV joints consist of several components, including inner and outer raceways, ball bearings or rollers, a cage or retainer, and a protective boot. These components work together to allow for smooth rotation and articulation while transmitting torque from the transmission to the wheels.

Signs of CV Joint Failure:

Common signs of CV joint failure include clicking or popping noises during turns, vibration or shaking during acceleration, and grease leakage from the CV joint boot. If left unaddressed, CV joint failure can lead to loss of vehicle control and potentially costly repairs.

CV Joint Maintenance:

Regular inspection and maintenance of CV joints are essential for ensuring optimal performance and longevity. This includes checking for signs of wear or damage, inspecting CV joint boots for tears or cracks, and ensuring proper lubrication of the CV joint components.

Replacement of CV Joints:

If a CV joint becomes worn or damaged beyond repair, it may need to be replaced. Replacement typically involves removing the old CV joint and installing a new one, along with replacing any damaged CV joint boots or components. It’s essential to use high-quality replacement parts and follow proper installation procedures to ensure reliable performance.

CV Joint Upgrades:

In some cases, vehicle owners may choose to upgrade their CV joints to aftermarket or performance-oriented alternatives. Upgraded CV joints may offer improved durability, strength, and performance characteristics, making them suitable for high-performance or off-road applications.

CV Joints in Different Vehicle Systems:

CV joints are commonly found in front-wheel drive, all-wheel drive, and four-wheel drive vehicles, where they play a crucial role in transmitting torque from the transmission to the wheels. They are also used in other applications, such as industrial machinery and agricultural equipment, where smooth and consistent power transmission is essential.

Importance of CV Joints in Vehicle Performance:

CV joints play a critical role in ensuring stable and predictable vehicle handling, especially during acceleration, braking, and steering maneuvers. By allowing for smooth and consistent power delivery to the wheels, CV joints contribute to overall vehicle performance, safety, and drivability. Regular inspection, maintenance, and timely replacement of CV joints are essential for preserving vehicle performance and reliability.

A constant-velocity joint (CV joint) is a crucial component in the drivetrain of vehicles, particularly those with front-wheel drive, all-wheel drive, or four-wheel drive systems. CV joints play a vital role in transmitting torque from the engine to the wheels while accommodating the vehicle’s suspension movement and allowing for smooth and consistent power delivery, even during steering maneuvers. Understanding the function, types, and maintenance of CV joints is essential for ensuring optimal vehicle performance and longevity.

CV joints facilitate the transfer of torque from the transmission to the wheels while accommodating the articulation and movement of the vehicle’s suspension system. They allow for smooth and consistent power delivery to the wheels, even during steering and suspension movements, ensuring stable and predictable vehicle handling and performance.

There are several types of CV joints, including the Rzeppa joint, ball-type CV joint, and tripod joint. Each type has its unique design and configuration, but they all serve the same fundamental purpose of transmitting torque while accommodating articulation and movement in the drivetrain.

CV joints consist of several components, including inner and outer raceways, ball bearings or rollers, a cage or retainer, and a protective boot. These components work together to allow for smooth rotation and articulation while transmitting torque from the transmission to the wheels.

Common signs of CV joint failure include clicking or popping noises during turns, vibration or shaking during acceleration, and grease leakage from the CV joint boot. If left unaddressed, CV joint failure can lead to loss of vehicle control and potentially costly repairs.

Regular inspection and maintenance of CV joints are essential for ensuring optimal performance and longevity. This includes checking for signs of wear or damage, inspecting CV joint boots for tears or cracks, and ensuring proper lubrication of the CV joint components.

If a CV joint becomes worn or damaged beyond repair, it may need to be replaced. Replacement typically involves removing the old CV joint and installing a new one, along with replacing any damaged CV joint boots or components. It’s essential to use high-quality replacement parts and follow proper installation procedures to ensure reliable performance.

In some cases, vehicle owners may choose to upgrade their CV joints to aftermarket or performance-oriented alternatives. Upgraded CV joints may offer improved durability, strength, and performance characteristics, making them suitable for high-performance or off-road applications.

CV joints are commonly found in front-wheel drive, all-wheel drive, and four-wheel drive vehicles, where they play a crucial role in transmitting torque from the transmission to the wheels. They are also used in other applications, such as industrial machinery and agricultural equipment, where smooth and consistent power transmission is essential.

CV joints play a critical role in ensuring stable and predictable vehicle handling, especially during acceleration, braking, and steering maneuvers. By allowing for smooth and consistent power delivery to the wheels, CV joints contribute to overall vehicle performance, safety, and drivability. Regular inspection, maintenance, and timely replacement of CV joints are essential for preserving vehicle performance and reliability.