Innovations, innovations, innovations! Advanced developments, including organic electronics, artificial intelligence (AI), the Internet of Things (IoT), and 3D-printed electronics, are transforming the electronics manufacturing business.

Carbon-based organic electronics are flexible, lightweight, and biodegradable. With smart automation, predictive maintenance, and quality control, AI is transforming manufacturing. IoT lets devices share data and optimize processes in real-time, enhancing factory efficiency. Innovative design and manufacture are possible with 3D-printed electronics, which now rapidly create sophisticated, unique components at a reduced cost. These developments are expanding electronics’ possibilities, making the future brighter and more fascinating.

Printed Circuit Boards (PCB) Design and LED Polarity

PCBs are useful tools for LEDs. They are thin boards made of metal, fiberglass, or other materials that connect computer parts electrically. Many LED applications need these boards, which are also known as PCBs.

Preventing electrical difficulties and optimizing device performance requires proper LED placement and orientation on PCBs. If you don’t connect LEDs correctly, the circuit fails, which affects how the PCB works. It is essential to design the PCB layout with the right LED Polarity. Early checking of the LED polarity prevents mistakes during production, ensures the board works and avoids expensive reworks. This approach ensures that the building process goes smoothly and keeps parts from getting damaged.

The electronic manufacturing industry is expanding and now leveraging advanced materials, organic electronics, and miniaturization. The following are the top 10 key innovation trends to look out for in 2024.

1. Advanced Electronic Materials

Silicon has been the primary material in the electronics business for many years, but it is hard to work with. New materials and designs, like silicon alternatives, graphene, and nanomaterials, are now the center of innovation. GaN (Gallium Nitride) semiconductor material is often used to make vertical current transmission devices that handle voltages from 1000V to over 10,000V.

It’s used in electric cars, industrial motor control, and the energy grid. Carbon nanotube processing is a semiconductor-grade material deposited at room temperature. It is useful for making many high-performance transistor channels, which makes it useful for parts used in sensors, computers, and wireless networks.

2. Organic Electronics

Organic electronics are better than standard artificial ones in many ways, such as being cheaper, more flexible, optically clear, lighter, and using less power. As people learn more about sustainable development and eco-friendly making, an increasing number of electronics and circuits are being made with organic materials. This method creates new business prospects and a competitive edge by using safer, fewer, and more raw materials.

Organic electronics include the following:

- Electron transport materials

- Injection materials

- Light-emitting materials

- Coating materials

- Displays materials

- Illumination materials

- Solar cell materials

Additionally, a low-cost light source based on organic fluorescent semiconductors, organic semiconductor laser diode technology integrates seamlessly with OLED and organic electronic platforms.

3. AI

AI-powered engineering tools find compatible parts with existing data blocks to automate steps that used to be done by hand in the engineering process. With just one click, these platforms let you create and make blueprints and PCB-floor plans. They work with all electronics production settings that are already in place. This lets companies shorten the time and effort needed to make new products.

4. Embedded Systems

Electronic gadgets depend on embedded systems to control their speed, security, size, and power. The world is becoming more and more connected, and there is a high demand for these systems. This has led to improvements in their speed, security, and ability to join.

Processor-level security solutions keep devices safe from threats that come from the network by watching and filtering orders based on rules for privacy, safety, and security. Adding this technology to embedded systems helps makers deal with security issues on devices.

An open-source, real-time orchestrator for distributed architectures makes it easier to build, test, and launch embedded apps by separating hardware and software tasks into small pieces called microservices.

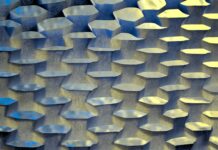

5. Printed Electronics Technology

As printing technologies are getting better, 3D-printed electronic devices are becoming popular. The delamination method separates flexible circuits from their stiff carriers. This lets high-performance devices be made on flexible materials without affecting the performance of the devices or the way they are made. This way is less expensive, better for the environment, and gets around the problems with clarity and dependability that come with printed electronics.

Circular and Hybrid Printed Electronics (HPE) includes printing from sheet to sheet and roll to roll, photonic sintering, stencil printing, component assembly, and more. It has a smaller carbon footprint and is used in the lighting, automobile, healthcare, and electronics industries.

6. IoT

IoT is changing the way gadgets are made by challenging traditional manufacturing methods. It enables new ways of controlling devices and managing data that are difficult to achieve with conventional approaches. Moreover, it lets machines store and handle data independently while being linked to the internet.

For IoT applications, it’s essential to make changes to how sensors are made. For products to switch to 5G, they need new chips with efficient designs that are also cheaper. Integrated circuits for IoT sensor nodes use CMOS technology to cut costs without affecting performance. There are also IoT connectivity tools available.

7. Advanced Integrated Circuit (IC) Packaging

Chip packing and chip design have both been very popular recently. Moore’s law-based scaling isn’t as useful as it used to be for modern devices. Putting several complicated gadgets in a high-tech package is another way to reap the benefits of scaling. So, companies that make semiconductors are coming up with new, more advanced IC packing methods to allow more silicon to fit into packages that are getting smaller and smaller.

Manufacturers offer customization and higher outputs with this new technology. It lets them stack flexible parts vertically. Also, advanced IC packaging makes production more efficient so that costs and customer needs are balanced.

8. 3D Printing

In the electronics business, additive manufacturing gets rid of the need for flat circuit boards, which makes it possible to make new shapes and patterns. 3D printers now make electronic parts as a single, continuous piece. This speeds up development, allows for mass customization, and spreads out the production of parts.

This technology has made it possible to build things in 3D and find new ways to stack circuits. 3D nanofabrication for photonic integration allows in situ printing of beam-shaping devices, overcoming large-scale assembly problems. Atomic layer 3D printing simplifies micro and nanodevice prototypes and manufacture by developing and producing materials, devices, and microsystems with atomic precision.

9. Miniaturized Electronics

Miniaturization has changed how gadgets are used in many areas, such as healthcare and cars. The concept was restricted by practical handling, display, and battery. However, it is being developed to make electrical components as compact as feasible while keeping speed, reliability, and efficiency. Nanonet sensors and worksheet FET are two new technologies.

The atomic layer etching (ALE) approach produces nanostructures below 20 nm, allowing cost-effective transistor channel scaling at sub-20 nm technology nodes. The latest wafer-scale hyperspectral filter technology and CMOS integration are used to provide miniaturized integrated spectral sensing systems. These monitors are the right size, use the right amount of power, and don’t cost too much for mobile devices.

10. Immersive Technologies

People who work in electronics often make mistakes, which result in slowing down the process. By looking at design items at different sizes, immersive technologies help get rid of flaws in goods while they are still being designed. These technologies find mistakes in both the design and the production process, like slivers, missing solder pads, and connections that don’t have enough power.

In addition, they also make it easier to train employees, make prototypes, and keep assemblies in good shape. An augmented reality (AR) toolkit for printed circuit board (PCB) production and workflow testing connects PCB design data to calibration pictures. This lets businesses quickly and easily check, debug, rework, and put together PCBs. Visually supporting complicated processes, the AR-based assembly aid gives instant error notifications, which eliminates human mistakes and reduces work.

Shaping the Future: Innovations in Electronics Manufacturing

In conclusion, these trends in electronics manufacturing will facilitate the move towards smart and flexible manufacturing methods. In general, manufacturers will be most interested in making small, efficient parts used in specific situations in the future. These goals need to be reached with the help of cutting-edge materials and cutting-edge printing and packing methods.

In the same way, switching to organic technology lets businesses deal with the worldwide problem of electrical waste and environmental issues. New technologies like big data and analytics are also changing business, helping people make better decisions.