Autonomous assembly lines powered by AI are quickly reshaping the manufacturing landscape, introducing unprecedented levels of efficiency, precision, and flexibility. These cutting-edge systems, which rely on a combination of robotics, AI, and real-time data analytics, are transforming the production process across industries. By automating repetitive tasks and optimizing workflows, AI-driven autonomous assembly lines enable manufacturers to increase productivity, reduce costs, and ensure higher quality. As AI continues to advance, the capabilities of these systems will only improve, offering significant advantages to companies that implement them. In this article, we explore 10 game-changing facts about AI in autonomous assembly lines, highlighting the major benefits and the future of intelligent manufacturing.

1. Increased Efficiency and Productivity

One of the most impactful benefits of AI in autonomous assembly lines is the substantial increase in efficiency and productivity. AI-powered systems can manage tasks with high precision and speed, reducing production time and minimizing human error. These systems can work continuously without fatigue, performing repetitive tasks such as assembly, inspection, and packaging at an accelerated rate. As a result, manufacturers can produce more products in less time, leading to a significant boost in overall productivity.

2. Real-Time Monitoring and Analytics

AI-driven autonomous assembly lines are equipped with sensors and advanced data analytics tools that provide real-time monitoring of every stage of the production process. These systems collect and analyze data from various points in the assembly line, allowing manufacturers to identify inefficiencies, potential issues, or delays before they escalate. With real-time insights, companies can make informed decisions and optimize their production process, reducing downtime and improving the overall quality of the finished products.

3. Reduced Human Error and Increased Precision

Human error can be costly in manufacturing environments, particularly in tasks that require high levels of precision. Autonomous assembly lines powered by AI minimize this risk by using robots and automated systems to perform tasks with consistent accuracy. These systems are capable of intricate operations such as welding, painting, and assembly, all while maintaining high standards of quality. As AI continues to improve, the precision of autonomous systems will become even more refined, leading to fewer defects and higher-quality products.

4. Cost Reduction and ROI

Implementing AI in autonomous assembly lines can result in significant cost savings over time. Although the initial investment in AI technology may be high, the long-term benefits far outweigh the costs. Reduced labor costs, fewer product defects, and increased production rates lead to a higher return on investment (ROI) for manufacturers. Additionally, by minimizing waste and optimizing resource usage, AI-driven systems help companies reduce operational costs, contributing to greater profitability in the long run.

5. Predictive Maintenance and Downtime Reduction

AI enables autonomous assembly lines to predict when maintenance is required, reducing the likelihood of unexpected breakdowns. By analyzing data from various sensors embedded in machines and robotic arms, AI systems can detect early signs of wear and tear, enabling maintenance teams to address issues before they cause costly downtime. Predictive maintenance helps keep assembly lines running smoothly, ensuring that production schedules are met and that unplanned interruptions are minimized.

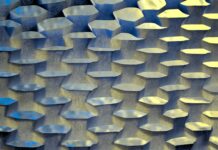

6. Flexibility and Adaptability

Autonomous assembly lines powered by AI are highly flexible and adaptable, making them ideal for industries that require frequent changes in production or customization. Unlike traditional assembly lines, which often require manual reconfiguration for different products, AI-driven systems can quickly adjust to new tasks without the need for significant downtime or retooling. This flexibility enables manufacturers to respond more effectively to market demands, allowing them to produce a wider variety of products with greater efficiency.

7. Improved Supply Chain Management

AI in autonomous assembly lines extends beyond the production process, integrating with supply chain management systems to optimize inventory, procurement, and logistics. AI systems can predict demand and adjust production schedules accordingly, ensuring that the right materials are available at the right time. By integrating supply chain data with real-time production analytics, AI helps manufacturers reduce waste, improve inventory management, and streamline the flow of goods, ultimately enhancing the entire supply chain process.

8. Enhanced Worker Safety

AI-powered autonomous assembly lines improve worker safety by reducing the need for human interaction with dangerous machinery. Robots and automated systems can perform high-risk tasks, such as handling hazardous materials or working in environments with extreme temperatures, while humans focus on supervisory roles. This reduces the risk of workplace accidents and injuries, creating a safer and more productive work environment for employees. As AI technology continues to evolve, these systems will become even more capable of ensuring safety and reducing human exposure to dangerous conditions.

9. Sustainable Manufacturing Practices

AI-driven autonomous assembly lines contribute to sustainability by optimizing resource use and reducing waste. Through real-time data analysis, AI can identify areas where energy consumption, material usage, and waste generation can be minimized. Autonomous systems can also monitor environmental conditions and ensure that production processes are more energy-efficient, leading to a reduction in carbon footprints. By adopting AI, manufacturers can align with sustainability goals while maintaining high productivity and profitability.

10. The Future of Autonomous Assembly Lines: AI and Beyond

The future of autonomous assembly lines is closely tied to the continued evolution of AI. As AI technology becomes more advanced, autonomous systems will become even more intelligent, capable of handling increasingly complex tasks. We can expect to see further developments in AI-powered robots, advanced sensors, and data analytics that will further enhance the efficiency, precision, and flexibility of autonomous assembly lines. As these technologies progress, manufacturers will have even more opportunities to improve their operations, stay competitive in the marketplace, and drive innovation in their industries.

Conclusion: Embracing the Future of Manufacturing with AI

The integration of AI into autonomous assembly lines is revolutionizing the manufacturing industry by offering increased efficiency, reduced costs, and enhanced precision. As businesses continue to adopt AI technologies, the benefits of automation will become even more pronounced, driving greater productivity and profitability. The future of manufacturing lies in the ability to adapt and evolve with cutting-edge technologies, and AI-powered autonomous assembly lines are at the forefront of this transformation. By embracing these innovations, manufacturers can position themselves for long-term success and remain competitive in an increasingly fast-paced and technology-driven world.