Metalworking, an ancient and fundamental craft, encompasses a wide range of processes involved in shaping, cutting, and joining metals to create intricate and functional structures. This age-old practice, dating back thousands of years, has evolved significantly with the advancement of technology, giving rise to modern techniques that have revolutionized industries and enabled humanity to forge impressive achievements in engineering, architecture, and art. Metalworking has been a cornerstone of human civilization, playing a pivotal role in the development of societies and shaping the course of history.

The roots of metalworking can be traced back to the Bronze Age when humans discovered the art of smelting metals like copper and tin to produce bronze, an alloy that proved stronger and more durable than its individual components. The Bronze Age marked a significant leap forward in human capabilities, enabling the creation of tools, weapons, and artifacts that transformed daily life. As civilizations flourished and trade networks expanded, metalworking techniques spread across continents, leading to the discovery of new metals like iron and steel, further propelling human progress.

Metalworking encompasses a wide array of processes, each tailored to specific applications and materials. Forging, one of the oldest techniques, involves shaping metal through heat and pressure, often using a hammer and anvil. Blacksmiths skillfully mold metals into various forms, from simple tools to intricate wrought iron designs. Casting, on the other hand, involves pouring molten metal into molds, allowing for the creation of complex shapes and structures, such as engine components and ornate sculptures.

Machining, a hallmark of modern metalworking, involves the use of cutting tools to remove material from a workpiece, resulting in precise and intricate shapes. With the advent of computer numerical control (CNC) machining, the process has become highly automated and capable of producing complex geometries with exceptional accuracy and efficiency. CNC machining has revolutionized industries such as aerospace, automotive, and electronics, enabling the production of critical components that require tight tolerances and superior performance.

Welding, an essential joining process in metalworking, involves fusing two or more metal pieces together using heat and pressure. This versatile technique allows the creation of robust and durable connections, making it indispensable in industries ranging from construction to shipbuilding. Welders skillfully manipulate various welding methods, such as arc welding, gas welding, and laser welding, to suit different materials and project requirements.

Sheet metal fabrication is another vital aspect of metalworking, focusing on the manipulation of thin metal sheets into functional and aesthetic components. This process finds application in the creation of enclosures, cabinets, and architectural elements, where precision and attention to detail are paramount. Sheet metal workers employ techniques like bending, cutting, and forming to transform flat sheets into three-dimensional structures.

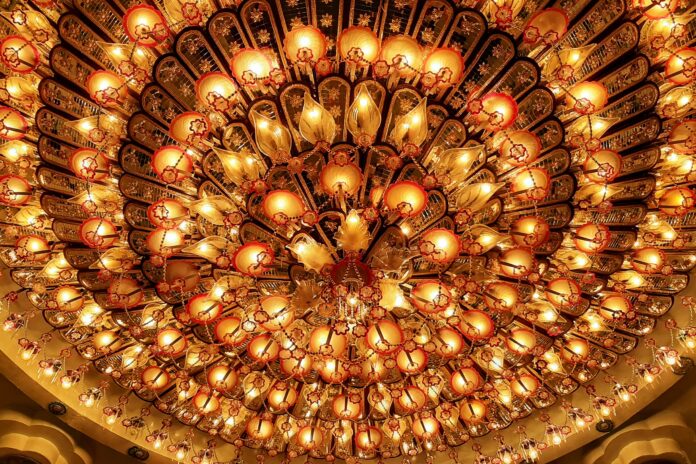

Metalworking also extends its influence into the realm of art and design. Sculptors and artisans leverage metal as a medium to express creativity and craft awe-inspiring works of art. The combination of traditional metalworking techniques with contemporary artistic vision has given rise to breathtaking sculptures, intricate jewelry, and unique decorative pieces that resonate with audiences across the globe.

As technology progresses, metalworking continues to evolve with the advent of advanced materials and cutting-edge processes. Additive manufacturing, commonly known as 3D printing, has emerged as a transformative force in metalworking, enabling the production of complex geometries and customized parts with unparalleled precision. By building up layers of metal powder and fusing them together with lasers, 3D metal printing has expanded design possibilities and streamlined rapid prototyping and low-volume production.

The application of metalworking techniques is far-reaching, underpinning critical infrastructure and machinery essential for modern living. From skyscrapers that define city skylines to intricate medical instruments that save lives, metalworking forms the backbone of industries that drive progress and innovation. The energy sector relies on metalworking to produce components for power generation and distribution, while the transportation sector employs it to manufacture automobiles, airplanes, and ships that connect the world.

In the realm of defense and security, metalworking plays a vital role in crafting military equipment, armored vehicles, and aircraft components that ensure national safety and sovereignty. Precision and reliability are non-negotiable in these applications, making metalworking a cornerstone of national defense strategies.

Metalworking is not limited to large-scale industrial applications; it also impacts daily life in countless ways. From the cutlery we use at the dining table to the household appliances that simplify chores, metalworking touches our lives in the most mundane yet essential aspects. Even our smartphones, with their sleek aluminum bodies and precision-machined components, owe their existence to the expertise of metalworkers.

However, the practice of metalworking is not without its challenges. As technology advances, so do the demands for sustainable and eco-friendly practices. Metalworking processes consume significant amounts of energy and produce waste materials that require responsible disposal. The industry is embracing the principles of sustainability, exploring ways to reduce energy consumption, recycle scrap metal, and minimize the environmental impact of metalworking processes.

Moreover, the mastery of metalworking requires a skilled and dedicated workforce. Metalworkers undergo years of training and hands-on experience to hone their craft. As technology evolves, so must the workforce, adapting to new techniques and digital tools that shape the future of metalworking.

In conclusion, metalworking stands as a cornerstone of human progress, transforming raw materials into structures that have shaped societies and defined eras. From the dawn of civilization to the digital age, metalworking has evolved alongside humanity, offering innovative solutions and pushing the boundaries of what is possible. As technology continues to advance, metalworking will remain a driving force behind progress, enabling creativity, sustainability, and connectivity in the world we live in.

Ancient Craftsmanship:

Metalworking is an age-old practice that dates back to ancient civilizations, playing a pivotal role in shaping human progress and development.

Versatile Processes:

Metalworking encompasses a wide range of techniques, including forging, casting, machining, welding, and sheet metal fabrication, each tailored to specific applications and materials.

Evolution with Technology:

Metalworking has evolved with technological advancements, embracing modern techniques such as CNC machining and additive manufacturing (3D printing) to revolutionize industries and design possibilities.

Critical Industries:

Metalworking forms the backbone of critical industries, including aerospace, automotive, construction, and defense, providing essential components and structures for modern living and national security.

Art and Creativity:

Metalworking extends beyond industrial applications, influencing art and design with awe-inspiring sculptures, intricate jewelry, and decorative pieces that showcase the fusion of traditional craftsmanship and contemporary artistic vision.

Additive Manufacturing:

The advent of 3D metal printing has transformed metalworking, enabling the production of complex geometries and customized parts with exceptional precision and efficiency.

Sustainable Practices:

Metalworking is embracing sustainability principles, exploring ways to reduce energy consumption, recycle scrap metal, and minimize environmental impact, aligning with the global drive for eco-friendly practices.

Daily Life Applications:

Metalworking impacts daily life in various ways, from household appliances and cutlery to smartphones and electronics, enhancing our modern lifestyles and conveniences.

Skilled Workforce:

Mastery of metalworking requires a skilled and dedicated workforce, with metalworkers undergoing extensive training and hands-on experience to excel in their craft.

Driving Human Progress:

Throughout history and into the future, metalworking remains a driving force behind human progress, innovation, and connectivity, shaping societies and defining eras.

Metalworking, a craft with ancient roots, has stood the test of time and remains an integral part of human civilization. From the earliest civilizations to the digital age, metalworking has continually evolved, adapting to technological advancements and driving human progress. This enduring practice involves the shaping, cutting, and joining of metals to create a vast array of products and structures that define our modern world.

The history of metalworking can be traced back thousands of years, with the emergence of copper and bronze as the first metals to be utilized by early human societies. The discovery that heating copper ores could produce a malleable metal marked a turning point in human technological development. Bronze, an alloy of copper and tin, proved to be even more durable and versatile, leading to its widespread use for tools, weapons, and various artifacts.

As civilizations expanded and trade networks flourished, the knowledge of metalworking spread across continents. The discovery of iron, an abundant and robust metal, revolutionized metalworking practices. Ironworking techniques allowed for the creation of stronger tools and weapons, transforming warfare and agriculture. Iron’s versatility and prevalence in various regions contributed to its pivotal role in shaping human societies.

The mastery of metalworking was a closely guarded skill, passed down through generations of skilled artisans and blacksmiths. These craftsmen held a special place in society, as their expertise was critical to the development of infrastructure, transportation, and trade. The craft of metalworking became intertwined with cultural and economic growth, laying the foundation for technological advancements in the ancient world.

The Middle Ages witnessed significant advancements in metalworking techniques. The rise of feudal societies and the construction of cathedrals and castles spurred innovation in iron and steel production. Techniques like water-powered hammers and bellows facilitated the mass production of metal goods, contributing to the growth of urban centers and the emergence of skilled guilds.

The Renaissance era marked a period of artistic and technical resurgence, with metalworking finding expression in intricate designs and ornate decorations. Skilled metalworkers crafted exquisite jewelry, intricate armor, and decorative elements for churches and palaces. The fusion of artistry and craftsmanship elevated metalworking to a form of artistic expression.

The Industrial Revolution in the 18th and 19th centuries brought about transformative changes in metalworking. Advancements in machinery and steam power revolutionized manufacturing, leading to the mass production of metal goods. The mechanization of metalworking processes accelerated industrialization and fueled economic growth, shaping the modern world and the way goods were produced and distributed.

The 20th century witnessed remarkable breakthroughs in metallurgy and metalworking technologies. The development of new alloys and materials, such as stainless steel and aluminum, expanded the possibilities for metal applications. The use of electricity in welding processes revolutionized the joining of metals, offering faster and more efficient methods for creating sturdy connections.

The Second World War further accelerated advancements in metalworking, as industries focused on producing weaponry, aircraft, and other military equipment. The demands of war spurred innovation in metalworking techniques, leading to the widespread adoption of arc welding, sheet metal fabrication, and precision machining.

The post-war era saw metalworking technologies trickle into civilian applications, transforming various industries. The automotive sector benefited from mass-produced steel frames, enabling the production of affordable and reliable vehicles. The construction industry embraced reinforced concrete and steel structures, revolutionizing urban landscapes and architecture.

The advent of computer technology in the latter half of the 20th century ushered in a new era for metalworking. Computer-aided design (CAD) and computer numerical control (CNC) machining revolutionized design and manufacturing processes. The integration of computers with metalworking equipment allowed for precision and repeatability in producing complex components and structures.

In recent decades, additive manufacturing, commonly known as 3D printing, has emerged as a disruptive force in metalworking. This cutting-edge technology allows for the creation of intricate and customized metal parts through layer-by-layer deposition of metal powders. 3D metal printing has found applications in aerospace, healthcare, and engineering, revolutionizing prototyping and low-volume production.

The digital age has also facilitated globalization in metalworking. The ease of sharing information and designs across the world has led to collaborative efforts between metalworking specialists from different regions. Digital platforms and online marketplaces have opened new avenues for metalworkers to showcase their products and reach global audiences.

In addition to its industrial applications, metalworking plays a significant role in the art world. Sculptors and artisans harness metal as a medium for their creativity, producing awe-inspiring sculptures, decorative pieces, and architectural installations. The fusion of traditional metalworking techniques with modern artistic sensibilities has resulted in striking works of art that challenge perceptions and push the boundaries of creativity.

Metalworking has also played a vital role in preserving cultural heritage. Historical restoration projects often involve skilled metalworkers who repair and recreate intricate metal elements in ancient buildings and artifacts. The expertise of these artisans ensures that the legacy of past civilizations is safeguarded for future generations.

As metalworking techniques have evolved, so have the challenges and opportunities facing the industry. Sustainability has become a pressing concern, as metalworking processes consume significant amounts of energy and generate waste materials. Metalworkers and manufacturers are increasingly embracing sustainable practices, exploring ways to recycle scrap metal, reduce energy consumption, and minimize the environmental impact of metalworking processes.

Moreover, the digitization of metalworking presents both challenges and opportunities for the workforce. While automation and CNC machining have streamlined processes, they have also necessitated the acquisition of digital skills and adaptability. The metalworking industry must balance the integration of advanced technologies with the preservation of traditional craftsmanship.

In conclusion, metalworking’s rich history, from ancient times to the modern era, showcases its enduring relevance and transformative impact on human progress. The craft of shaping and joining metals has evolved alongside technological advancements, powering industries and defining cultural and artistic expression. As metalworking continues to adapt to the digital age, its capacity for innovation and creativity remains boundless. From the intricate craftsmanship of ancient blacksmiths to the cutting-edge technologies of today, metalworking stands as a testament to human ingenuity and the remarkable potential of shaping raw materials into structures that shape our world.