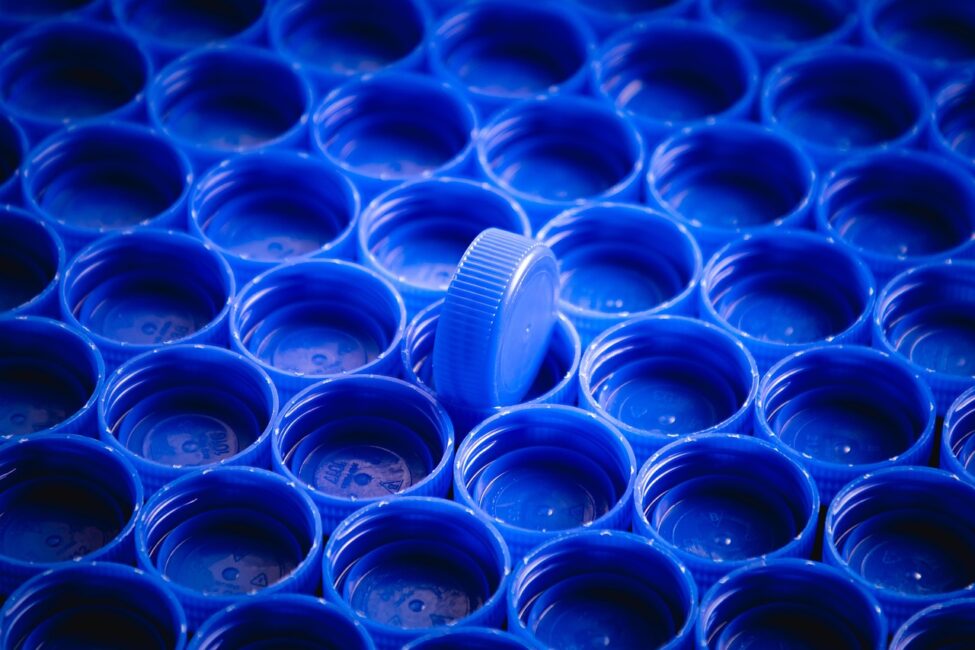

Injection molding is a well-established manufacturing process that has been used for decades to create plastic parts and products in various industries. When considering the best method for your production needs, opting for custom injection molding can provide numerous advantages over standard manufacturing techniques. Custom injection molding offers flexibility, precision, and cost-effectiveness, making it the preferred choice for many businesses. Let’s explore six key benefits of choosing custom injection molding for your next project.

Precision and Accuracy

One of the greatest benefits of custom injection molding is the level of precision it offers. The process allows for the creation of parts with high dimensional accuracy and tight tolerances. Whether you’re producing complex components for electronics or intricate parts for automotive applications, custom injection molding can meet your specifications with remarkable precision. This level of accuracy ensures that each part fits perfectly with its counterpart, leading to fewer defects and less rework. By selecting custom molds tailored to your needs, you can achieve consistently high-quality products with every batch.

Cost-Effectiveness for High Volumes

Another major advantage of custom injection molding is its ability to provide cost savings in high-volume production runs. Once the mold is created, the process becomes relatively inexpensive for large-scale manufacturing. This makes injection molding an ideal solution for producing large quantities of uniform parts. Custom molds allow for the production of thousands or even millions of parts in a short amount of time, which reduces the overall cost per unit.

Custom injection molding is particularly beneficial for businesses that need to scale their production quickly and efficiently. With such a streamlined process, working with AIM or any other reliable company can optimize manufacturing costs, ensuring you receive high-quality products at competitive prices. The precision and consistency offered by custom injection molding ensure that each part meets exact specifications, reducing the need for costly rework or quality control issues.

Versatility in Materials

Custom injection molding offers a wide range of material options, making it a versatile solution for various industries. Whether you require thermoplastics, thermosets, or elastomers, the process can accommodate a diverse selection of materials to meet your specific needs. Custom molds can be used with materials that are engineered for specific performance characteristics, such as heat resistance, durability, or flexibility. This flexibility gives businesses the ability to choose the material best suited for their application, ensuring that the end product meets performance and safety standards.

Reduced Waste and Increased Sustainability

In traditional manufacturing processes, a significant amount of material waste can occur. Custom injection molding, on the other hand, is a highly efficient process that minimizes waste. The precise control over the amount of material injected into the mold reduces the risk of excess material being used. Excess material can often be recycled and reused in subsequent runs, contributing to a more sustainable manufacturing process. As sustainability becomes an increasingly important factor for businesses, reducing waste through custom injection molding can help companies meet environmental goals while maintaining cost-effectiveness.

Complex Geometries and Design Flexibility

Custom injection molding enables the production of parts with intricate geometries and complex designs that would be difficult or impossible to achieve with other manufacturing methods. The process can handle undercuts, thin walls, and complicated internal features, which provides significant design flexibility. This capability is particularly valuable for industries like automotive, aerospace, and medical devices, where the need for high-performance components with complex shapes is common. Custom molds can be designed to create parts with multiple features in a single step, reducing the need for additional manufacturing processes and improving efficiency.

Faster Time to Market

Custom injection molding can significantly shorten the time it takes to bring a product to market. The ability to quickly design, prototype, and produce parts enables businesses to meet tight deadlines and respond rapidly to market demands. With the right custom mold, parts can be produced quickly and efficiently, helping companies get their products to consumers faster than ever before. Whether you are launching a new product or need to ramp up production for an existing one, custom injection molding can help you meet your goals with speed and precision.

At the heart of many successful manufacturing operations is the choice to partner with experts in custom injection molding. With a tailored approach to your production needs, companies can realize significant savings, increased efficiency, and a smoother overall process. Whether you are producing consumer goods, medical devices, or complex automotive parts, custom injection molding offers flexibility and precision that can take your production to the next level.

For businesses looking to streamline their manufacturing process and reduce operational costs, working with a reliable provider of custom injection molding solutions. By leveraging the expertise of specialists in the field, you can ensure that your parts are produced efficiently, cost-effectively, and to the highest standards.