Seegrid Corporation is a pioneering company in the field of robotics and automation, specializing in autonomous mobile robots (AMRs) for material handling and logistics applications. Since its founding in 2003, Seegrid has been at the forefront of innovation, revolutionizing the way businesses operate and manage their supply chains. With a commitment to safety, efficiency, and reliability, Seegrid has established itself as a leader in the rapidly evolving landscape of industrial automation.

1. Founding and History

Seegrid Corporation was founded in 2003 by Dr. Hans Moravec and Dr. Chris Urmson, both renowned experts in the field of robotics and autonomous systems. The company was born out of a vision to develop advanced technologies that would revolutionize the way materials are transported and handled in industrial environments. Since its inception, Seegrid has grown from a small startup to a global leader in the field, with a track record of innovation and excellence.

2. Autonomous Mobile Robots

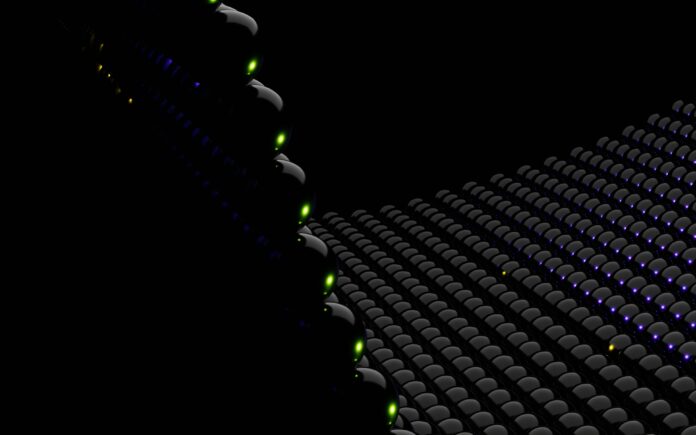

At the core of Seegrid’s offerings are its autonomous mobile robots, which are designed to navigate complex warehouse and manufacturing environments without the need for external infrastructure. These robots use a combination of sensors, cameras, and proprietary algorithms to perceive their surroundings and make intelligent decisions about how to move and interact with their environment. By leveraging advanced technology, Seegrid’s robots are able to operate safely and efficiently in dynamic and unpredictable environments.

3. Safety and Reliability

Safety is a top priority for Seegrid, and the company has invested heavily in developing robust safety features for its autonomous mobile robots. From obstacle detection and collision avoidance systems to fail-safe mechanisms and redundant sensors, Seegrid’s robots are designed to operate safely in busy industrial environments. Additionally, the company places a strong emphasis on reliability, with rigorous testing and validation processes to ensure that its robots meet the highest standards of performance and durability.

4. Flexibility and Scalability

One of the key advantages of Seegrid’s autonomous mobile robots is their flexibility and scalability. Whether it’s transporting pallets, bins, or other materials, Seegrid’s robots can be easily adapted to meet the specific needs of each customer. With a modular design and customizable software, Seegrid’s robots can be quickly reconfigured to handle different tasks and workflows, making them ideal for a wide range of material handling applications.

5. Integration with Warehouse Management Systems

Seegrid’s robots are designed to seamlessly integrate with existing warehouse management systems (WMS), allowing businesses to optimize their material handling processes and improve overall efficiency. By leveraging real-time data and analytics, Seegrid’s robots can help businesses identify opportunities for optimization and streamline their operations. Additionally, Seegrid offers a range of software tools and APIs that allow customers to customize and extend the functionality of their robotic systems.

6. Customer Support and Service

Seegrid is committed to the success of its customers and provides comprehensive support throughout the entire lifecycle of its products. From initial consultation and system design to installation, training, and ongoing maintenance, Seegrid works closely with customers to ensure they get the most out of their investment in autonomous mobile robots. With a team of experienced engineers and support staff, Seegrid is dedicated to providing prompt and reliable service to its customers around the clock.

7. Industry Recognition

Seegrid’s innovative technology and commitment to excellence have earned the company numerous awards and accolades in the field of robotics and automation. From industry organizations to media outlets, Seegrid has been recognized for its contributions to advancing the state of the art in material handling and logistics. These accolades serve as a testament to Seegrid’s dedication to pushing the boundaries of what’s possible in the world of industrial automation.

8. Global Presence

Headquartered in Pittsburgh, Pennsylvania, Seegrid Corporation has a global presence, with customers and partners located around the world. The company’s autonomous mobile robots are deployed in a wide range of industries, including manufacturing, warehousing, e-commerce, and more, helping businesses improve efficiency and productivity in diverse environments. With a network of distributors and service centers spanning the globe, Seegrid is able to provide localized support and service to its customers wherever they are located.

9. Continuous Innovation

Seegrid is dedicated to continuous innovation and invests heavily in research and development to stay at the forefront of the robotics and automation industry. The company is constantly exploring new technologies and techniques to improve the performance, capabilities, and reliability of its autonomous mobile robots, ensuring that they remain at the cutting edge of the industry. By staying ahead of the curve, Seegrid is able to anticipate and respond to the evolving needs of its customers and the market as a whole.

10. Future Outlook

As the demand for automation continues to grow, Seegrid is well-positioned to capitalize on the opportunities presented by the evolving landscape of material handling and logistics. With its proven track record of innovation, commitment to customer success, and global presence, Seegrid is poised to continue leading the way in autonomous mobile robotics for years to come. With a focus on safety, reliability, and flexibility, Seegrid’s robots offer businesses a scalable and cost-effective solution for streamlining their operations and adapting to the demands of modern supply chains.

Seegrid Corporation, founded in 2003 by Dr. Hans Moravec and Dr. Chris Urmson, has evolved into a global leader in the robotics and automation industry. The company’s core offering revolves around its autonomous mobile robots (AMRs), which are meticulously designed to navigate complex industrial environments without the need for external infrastructure. These robots utilize a sophisticated blend of sensors, cameras, and proprietary algorithms to perceive their surroundings, ensuring safe and efficient operation amidst dynamic and unpredictable environments.

Safety and reliability are paramount in Seegrid’s robotic solutions. The company invests heavily in developing robust safety features for its AMRs, including obstacle detection, collision avoidance systems, and redundant sensors. These measures, combined with stringent testing and validation processes, ensure that Seegrid’s robots meet the highest standards of performance and durability, instilling confidence in customers regarding their safety and reliability in demanding industrial environments.

Flexibility and scalability are hallmarks of Seegrid’s autonomous mobile robots. Whether it’s transporting pallets, bins, or other materials, these robots can be easily customized and adapted to meet the specific needs of each customer. With a modular design and customizable software, Seegrid’s robots can swiftly adapt to handle different tasks and workflows, offering versatility across a wide range of material handling applications.

Seegrid’s commitment to seamless integration extends to its compatibility with existing warehouse management systems (WMS). By integrating with WMS, Seegrid’s robots enable businesses to optimize their material handling processes and enhance overall efficiency. Real-time data and analytics provided by the robots empower businesses to identify areas for optimization, thereby streamlining operations and maximizing productivity.

Customer support and service are paramount at Seegrid. The company offers comprehensive support throughout the lifecycle of its products, including consultation, system design, installation, training, and ongoing maintenance. With a dedicated team of experienced engineers and support staff, Seegrid ensures prompt and reliable service to its customers, enabling them to maximize the value of their investment in autonomous mobile robots.

Seegrid’s innovative technology and commitment to excellence have earned the company widespread recognition in the robotics and automation industry. Awards and accolades from industry organizations and media outlets underscore Seegrid’s contributions to advancing the state of the art in material handling and logistics, reaffirming its position as a leader in the field.

Headquartered in Pittsburgh, Pennsylvania, Seegrid Corporation boasts a global presence, with customers and partners spanning across various industries worldwide. From manufacturing and warehousing to e-commerce and beyond, Seegrid’s autonomous mobile robots help businesses improve efficiency and productivity in diverse environments. With a network of distributors and service centers worldwide, Seegrid provides localized support and service to its customers, ensuring seamless operations across different regions.

Continuous innovation drives Seegrid’s success in the robotics and automation industry. The company remains committed to pushing the boundaries of technology through ongoing research and development efforts. By staying ahead of the curve and anticipating evolving market needs, Seegrid is well-positioned to continue leading the way in autonomous mobile robotics for years to come, empowering businesses to thrive in an increasingly automated world.

As the demand for automation continues to surge, Seegrid is poised to capitalize on the opportunities presented by the evolving landscape of material handling and logistics. With its unwavering focus on safety, reliability, and flexibility, Seegrid offers businesses a scalable and cost-effective solution for streamlining their operations and adapting to the demands of modern supply chains. Through innovation, dedication, and global reach, Seegrid remains at the forefront of the robotics revolution, shaping the future of industrial automation.