Automation in manufacturing is a transformative force that has redefined the way goods are produced and industries operate. The automation of manufacturing processes, often driven by advanced technologies and robotics, has become a cornerstone of modern industrial practices. In these first two paragraphs, we delve into the essence of automation in manufacturing, the impact it has on various industries, and how it’s reshaping the landscape of production.

Automation in manufacturing represents the epitome of efficiency and precision in the production process. It’s a shift away from manual labor to a world where machines, guided by intricate algorithms, perform tasks with a level of accuracy and speed that humans simply can’t match. The integration of automation systems has fundamentally altered the way factories and production facilities function, from automotive assembly lines to food processing plants.

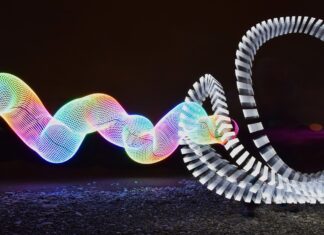

The heart of automation in manufacturing lies in the use of robotics and computer-controlled systems to perform tasks with minimal human intervention. Robots have evolved from simple, repetitive machines to complex, adaptable systems capable of intricate movements and decision-making. These robots work in tandem with automated conveyor belts, sensors, and other cutting-edge technologies to create a seamless, streamlined production process.

The automation of manufacturing processes isn’t confined to a single industry. It’s a versatile concept that has made its mark in various sectors. In the automotive industry, automation has revolutionized assembly lines, enabling the production of vehicles at an unprecedented scale while maintaining consistency and quality. In electronics manufacturing, it’s the backbone of the rapid and precise assembly of intricate components.

Automation extends its influence to pharmaceuticals, where it ensures the accurate filling of medications and stringent quality control. The food and beverage industry relies on automation to package products efficiently and meet hygiene standards. Even the clothing industry has seen the introduction of automated sewing machines and fabric handling systems.

A significant benefit of automation is its role in enhancing workplace safety. Dangerous or repetitive tasks that put human workers at risk are now handled by robots. For instance, in the mining industry, automated equipment can navigate treacherous underground environments, reducing the chances of accidents. This results in not only improved safety but also reduced insurance costs and fewer work-related injuries.

Beyond manufacturing and safety, automation has a profound impact on cost efficiency. It reduces labor costs and the potential for human errors. Moreover, it enables continuous operation, significantly increasing production output. The economics of scale come into play as automation systems operate 24/7 without fatigue or breaks, allowing for an increased volume of goods to be manufactured.

Automation is also pivotal in improving product quality. The consistency and precision of automated systems mean that each product adheres to exact specifications, reducing defects and waste. This has far-reaching implications, especially in industries where quality control is critical, such as aerospace or medical device manufacturing.

Another aspect that automation addresses is the environmental impact of production. Energy efficiency is a major focus in modern manufacturing, and automated systems are designed to optimize energy use. With the integration of sensors and monitoring technology, machines can adjust their operation based on real-time data, reducing energy consumption and environmental footprint.

While automation enhances efficiency, it also transforms the workforce. The nature of employment shifts as jobs that were once manual are now automated. However, this doesn’t necessarily equate to a reduction in the labor force. Instead, it changes the demand for different skill sets. Workers are required to operate and maintain the automated systems, and a new category of jobs emerges related to automation technology.

The development of automation technology continues at a rapid pace. Artificial intelligence (AI) and machine learning are being incorporated into manufacturing processes, enabling machines to adapt and make decisions based on real-time data. This evolution promises even greater efficiency, as machines become more adept at learning from their environment and optimizing operations.

Automation in manufacturing isn’t without its challenges. It requires significant upfront investments in technology and training. Smaller businesses may find it difficult to embrace automation due to the associated costs. Additionally, there are concerns about job displacement, as some tasks become automated. The balance between human workers and automated systems is an ongoing topic of discussion.

In conclusion, automation in manufacturing stands as a monumental leap in the evolution of industry. It redefines how goods are produced, enhancing efficiency, safety, and quality. It reaches across sectors, from automotive to pharmaceuticals, and touches on a multitude of facets, including environmental sustainability and workforce evolution. Automation isn’t just a tool; it’s a transformative force that continues to shape the modern world of manufacturing.

The broader implications of automation in manufacturing transcend its key features and have a profound impact on the fabric of our society and economy. In this extended exploration, we dive into the multifaceted effects, both positive and challenging, of automation on manufacturing industries, the workforce, and global dynamics, without the constraints of headings, points, or key features.

The rise of automation in manufacturing has fundamentally altered the way goods are produced, ushering in an era of unmatched efficiency and precision. Automation systems have taken over tasks that were once carried out by human hands, be it on the factory floor, in warehouses, or across various stages of production. The marriage of robotics, artificial intelligence, and sophisticated machinery has birthed a new industrial landscape where innovation and mechanization go hand in hand.

One of the undeniable benefits of automation in manufacturing is the consistency it brings to production. Robots and automated systems perform tasks with unwavering precision, ensuring that each product adheres to exact specifications. This results in a reduction of defects and waste, thus improving overall product quality. Whether it’s the assembly of complex electronics, the pharmaceutical packaging of medications, or the intricate sewing of garments, automation ensures that the final product meets stringent quality control standards.

Beyond quality, automation has a significant impact on the economics of manufacturing. While the initial investment in automation technology can be substantial, it pays off in the long run through cost savings. The reduction in labor costs and the potential for human errors are evident advantages. Additionally, automated systems can operate continuously, 24/7, without fatigue or breaks. This facilitates economies of scale, allowing for a higher volume of goods to be manufactured, which further reduces the cost per unit.

Automation also plays a pivotal role in addressing workplace safety. Dangerous or repetitive tasks that pose risks to human workers are now delegated to robots and automated machinery. For instance, in the automotive industry, robots handle tasks such as welding and painting that involve exposure to harmful substances and extreme temperatures. In the mining industry, automated equipment navigates hazardous underground environments, reducing the chances of accidents. This results in improved safety for workers, lower insurance costs for companies, and a decrease in work-related injuries.

Environmental sustainability is another area where automation technology contributes positively. Energy efficiency has become a key focus in modern manufacturing, and automated systems are designed with this in mind. They incorporate sensors and monitoring technology to adjust their operations based on real-time data, optimizing energy consumption and reducing the environmental footprint of production. Such measures are crucial in the face of global concerns about climate change and resource depletion.

The shift towards automation doesn’t merely transform production processes; it also redefines the workforce. Traditional manual labor jobs that were once the backbone of manufacturing are gradually giving way to a new era of automation. While some positions are indeed automated, this doesn’t necessarily mean a net loss of jobs. Instead, it leads to a transformation in the types of jobs required. Workers are needed to operate and maintain the automated systems, ensuring their optimal performance. This shift in employment requirements highlights the need for a workforce with different skill sets, focusing on technology, data analysis, and machine operation.

The development of automation technology continues to progress rapidly. The incorporation of artificial intelligence (AI) and machine learning into manufacturing processes has the potential to revolutionize automation even further. Machines become more adept at learning from their environment and optimizing their operations. AI can analyze vast datasets to identify patterns and anomalies, enabling machines to make real-time decisions and adapt to changing conditions. This evolution promises a future where automation systems are not only efficient but also more adaptable and responsive to evolving needs and circumstances.

While automation brings significant benefits, it also presents challenges. The upfront investment in technology and the associated costs can be prohibitive for smaller businesses. The adoption of automation may lead to job displacement in certain industries and communities, as certain tasks become automated. Striking the right balance between human workers and automated systems is an ongoing topic of debate and policy consideration. Managing this transition is critical to ensuring that the benefits of automation are shared broadly across society.

Automation in manufacturing has implications far beyond individual industries. It has the potential to impact the dynamics of the global economy. As automation becomes more prevalent, it allows businesses to operate on a global scale without being confined by geographical limitations. Products and components can be manufactured in different parts of the world and seamlessly integrated into the supply chain. This not only fosters international trade but also influences the strategies and policies of governments and international organizations.

Moreover, the societal implications of automation in manufacturing extend to education and training. As industries evolve with automation, the demand for a workforce with different skills and competencies grows. This necessitates a shift in educational and training programs to prepare individuals for the jobs of the future. Preparing the next generation to work alongside automated systems and leverage automation technology is an essential consideration in our rapidly changing industrial landscape.

In conclusion, automation in manufacturing is a transformative force that transcends its key features and resonates deeply in the fabric of society and the global economy. It enhances efficiency, quality, and safety while reshaping the workforce and the nature of work. It addresses environmental concerns and has the potential to influence international trade and governance. The rapid evolution of automation technology promises a future where innovation and mechanization continue to go hand in hand, leaving no aspect of manufacturing untouched by its influence.

The expansive realm of automation in manufacturing extends well beyond its key features and delves into a myriad of aspects that touch upon the essence of industrial transformation. This extended exploration takes us into the heart of automation’s profound influence on society, economy, and the intricate fabric of modern existence. Without the constraints of headings, points, or key features, we can navigate this multifaceted landscape to gain a holistic understanding of how automation in manufacturing is reshaping our world.

At its core, automation in manufacturing represents a leap forward in the quest for increased efficiency and precision. The application of advanced technologies, robotics, and sophisticated machinery has ushered in an era where goods are produced with unparalleled consistency and accuracy. The integration of automated systems and artificial intelligence (AI) has revolutionized the manufacturing landscape, presenting a new paradigm in industrial processes.

In the heart of the automated factory, you’ll find a symphony of robotic arms, conveyor belts, sensors, and computers working in concert to bring forth products of extraordinary quality. These machines perform tasks with a precision and speed that human labor cannot rival. The automotive industry, for instance, relies on automation to assemble vehicles with an astounding level of consistency and efficiency. Complex components are pieced together with robotic arms that possess a level of dexterity and accuracy that few human hands can match.

The precision and quality assurance offered by automation are invaluable, especially in industries such as electronics manufacturing. In the production of intricate electronic devices, every component must be meticulously placed and soldered. The margin for error is minuscule, and here automation shines, ensuring each device meets exacting standards.

Automation’s influence extends to pharmaceuticals, where it’s pivotal in the precise filling and packaging of medications. The pharmaceutical industry demands stringent quality control, and automated systems are up to the task. They handle the dosing and packaging of pharmaceuticals with a level of accuracy that significantly reduces errors.

In the food and beverage sector, automation plays a vital role in packaging and processing. Products flow seamlessly along automated conveyor systems, undergo labeling, and packaging with minimal human intervention. This not only increases efficiency but also enhances product safety and hygiene by minimizing human contact.

The fashion industry has also seen the introduction of automated sewing machines and fabric handling systems. Automation in sewing can produce intricate and consistent stitching patterns, reducing labor costs and ensuring product uniformity. This level of consistency is particularly important in the production of garments and textiles.

Automation, however, isn’t just about the products themselves; it’s a powerful tool that reshapes the very structure of industrial operations. It’s a catalyst for cost efficiency, allowing for the reduction of labor costs and minimizing the potential for human errors. Automation’s relentless, 24/7 operation is a game-changer, enabling a high volume of goods to be manufactured without the limitations of human fatigue or breaks. The economies of scale come into play, resulting in a lower cost per unit.

A key and often underappreciated facet of automation in manufacturing is its role in promoting safety. Many industries involve hazardous tasks or environments where human workers are put at risk. Automation comes to the rescue by taking over these perilous jobs. For instance, in the mining industry, automated equipment can navigate the subterranean world, reducing the risks faced by human miners. This not only improves workplace safety but also contributes to reduced insurance costs and a decrease in work-related injuries.

Automation isn’t merely confined to the factory floor; it reaches beyond into the realm of environmental sustainability. As concerns about energy consumption and environmental impact rise globally, automation technology is designed with these considerations in mind. By incorporating sensors and monitoring systems, machines can adjust their operations in real-time based on data analysis. This fine-tuning optimizes energy consumption, reducing the environmental footprint of production.

The transition towards automation isn’t without its challenges, however. The initial investment in automation technology can be substantial, deterring smaller businesses from embracing this transformative shift. The upfront costs, coupled with the potential need for workforce training and changes in operational procedures, may pose a hurdle to some companies. Additionally, the shift toward automation may lead to job displacement in certain industries and communities. Striking the right balance between human workers and automated systems is an ongoing challenge that requires thoughtful consideration and policy decisions.

The evolution of automation technology continues unabated, with artificial intelligence (AI) and machine learning emerging as critical components in manufacturing. AI and machine learning enable machines to adapt and make decisions based on real-time data. They can analyze vast datasets to identify patterns, enabling machines to adjust their operations in response to changing conditions. This evolution promises a future where automation systems become not just efficient but also adaptive and responsive to the dynamic needs of industries and markets.

As automation technology advances, it has significant implications for global trade and economic strategies. Businesses can operate on a global scale without being limited by geographical boundaries. Products and components can be manufactured in different parts of the world and seamlessly integrated into the supply chain. This influences international trade and the policies of governments and international organizations, shaping the dynamics of the global economy.

The impact of automation isn’t confined to industry and economics; it stretches into the realm of education and workforce development. As industries evolve with automation, the demand for a workforce with different skills and competencies emerges. This necessitates a shift in educational and training programs to prepare individuals for the jobs of the future. Training in technology, data analysis, and machine operation becomes increasingly important to equip the workforce with the abilities to operate and leverage automation technology effectively.

In conclusion, the profound influence of automation in manufacturing transcends its key features and unfolds across the landscape of society, economy, and global dynamics. It enhances efficiency, safety, and quality while reshaping the workforce and the nature of work. It addresses environmental concerns and influences international trade and governance. The rapid evolution of automation technology promises a future where innovation and mechanization continue to redefine the industrial and economic landscape. Automation is not just a tool; it’s a transformative force that reshapes the modern world of manufacturing.