3D printing, also known as additive manufacturing, is a revolutionary technology that has gained significant popularity and impact in recent years. It enables the creation of three-dimensional objects by depositing successive layers of material based on a digital model or design. This process eliminates the need for traditional subtractive manufacturing techniques, such as cutting or drilling, and allows for the fabrication of complex geometries with precision and efficiency. 3D printing has found applications in various industries, including aerospace, automotive, healthcare, consumer products, and more. In this comprehensive overview, I will discuss ten important aspects of 3D printing, highlighting its principles, processes, materials, applications, and potential future developments.

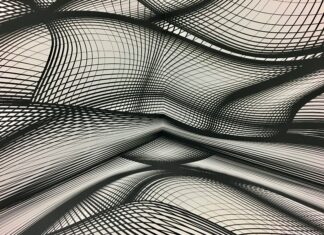

1. Principles of 3D Printing: 3D printing relies on the concept of layer-by-layer additive manufacturing. It starts with a digital 3D model created using computer-aided design (CAD) software. The model is then sliced into numerous thin cross-sectional layers, which serve as a blueprint for the 3D printer. The printer gradually builds the object by depositing material layer by layer, following the instructions from the sliced model.

2. 3D Printing Processes: Several 3D printing processes exist, each with its own characteristics and applications. Some common techniques include fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS), and digital light processing (DLP). These processes differ in the way they form and solidify the layers, the materials they can use, and the level of detail and accuracy they can achieve.

3. Materials for 3D Printing: A wide range of materials can be used for 3D printing, including plastics, metals, ceramics, composites, and even living cells in the field of bioprinting. Filament-based printers often use thermoplastics like PLA (polylactic acid) and ABS (acrylonitrile butadiene styrene). Meanwhile, metal 3D printers employ materials like stainless steel, titanium, aluminum, and nickel alloys. The availability of materials continues to expand, providing more options for various applications.

4. Applications of 3D Printing: 3D printing has found applications across numerous industries. In aerospace, it has been used to fabricate lightweight parts with complex geometries, reducing weight and improving fuel efficiency. In healthcare, it has enabled the production of custom prosthetics, implants, and medical models for surgical planning. The automotive industry employs 3D printing for rapid prototyping, tooling, and producing lightweight components. It is also utilized in the fashion and jewelry industries, architecture, education, and consumer products.

5. Advantages of 3D Printing: 3D printing offers several advantages over traditional manufacturing methods. It allows for the production of complex shapes and intricate designs that would be difficult or impossible to create using other techniques. It enables rapid prototyping, reducing development time and costs. 3D printing also allows for on-demand manufacturing, eliminating the need for large-scale production and reducing inventory storage. It promotes customization and personalization, enabling the creation of unique products tailored to individual needs.

6. Limitations and Challenges: Despite its many benefits, 3D printing still faces certain limitations and challenges. One limitation is the size of the objects that can be printed, as most printers have size restrictions. Additionally, 3D printing can be time-consuming, especially for larger objects with high-resolution requirements. The cost of 3D printers and materials can also be a barrier for some users. Furthermore, the mechanical properties and quality of printed parts may not always match those produced by traditional manufacturing methods.

7. Impact on Supply Chains: 3D printing has the potential to disrupt traditional supply chains by enabling localized and decentralized manufacturing. Instead of relying on large-scale production facilities in distant locations, products can be printed on-demand closer to the point of consumption. This can reduce shipping costs, lead times, and carbon emissions associated with transportation. It also allows for more flexible and responsive manufacturing, particularly for spare parts and customized products.

8. Intellectual Property and Legal Issues: The advent of 3D printing has raised concerns about intellectual property (IP) infringement. The ease of digital replication and distribution of designs has prompted discussions about protecting IP rights in the context of additive manufacturing. Issues such as copyright infringement and the unauthorized reproduction of patented objects have become more prominent. Addressing these challenges requires a balance between promoting innovation and protecting the rights of designers and manufacturers.

9. Environmental Sustainability: 3D printing has the potential to contribute to environmental sustainability in multiple ways. By enabling more efficient use of materials, it can reduce waste generated during manufacturing processes. The ability to create lightweight structures and optimize designs for material usage can also result in energy savings. Furthermore, localized manufacturing with 3D printing can reduce the carbon footprint associated with long-distance transportation. However, it is important to consider the environmental impact of the materials used for 3D printing and their disposal at the end of the product lifecycle.

10. Future Developments and Possibilities: The field of 3D printing continues to evolve rapidly, and ongoing research and development hold promising prospects. Innovations are being made in the development of new materials, including conductive and bioactive materials, expanding the potential applications of 3D printing. Advances in printer technology, such as increased printing speeds, larger build volumes, and higher resolution, are making 3D printing more accessible and efficient. Furthermore, the integration of 3D printing with other technologies, such as robotics and artificial intelligence, opens up new avenues for automation and customization.

3D printing is a transformative technology that has revolutionized the manufacturing landscape. Its layer-by-layer additive manufacturing process, diverse materials, and wide range of applications have made it a versatile tool in industries such as aerospace, healthcare, automotive, and more. While it offers numerous advantages, 3D printing also faces challenges and limitations. However, ongoing developments and research hold great promise for the future of this technology. As 3D printing continues to evolve, it will likely have a profound impact on industries, supply chains, intellectual property, sustainability, and manufacturing processes.

One of the notable impacts of 3D printing is its potential to disrupt traditional supply chains. By allowing localized and decentralized manufacturing, 3D printing reduces the dependence on large-scale production facilities in distant locations. Instead, products can be printed on-demand closer to the point of consumption. This shift can have significant implications, including reduced shipping costs, shorter lead times, and lower carbon emissions associated with transportation. Moreover, localized manufacturing with 3D printing offers more flexibility and responsiveness, particularly in scenarios involving spare parts or customized products.

However, the rise of 3D printing has also raised concerns about intellectual property (IP) infringement. The ease of digital replication and distribution of designs has sparked discussions about protecting IP rights in the context of additive manufacturing. Issues such as copyright infringement and the unauthorized reproduction of patented objects have become more prominent. Finding a balance between promoting innovation and safeguarding the rights of designers and manufacturers is crucial in addressing these challenges.

From an environmental standpoint, 3D printing has the potential to contribute to sustainability efforts. The technology enables more efficient use of materials, reducing waste generated during the manufacturing process. Additionally, the ability to create lightweight structures and optimize designs for material usage can lead to energy savings. Furthermore, the localized nature of 3D printing reduces the carbon footprint associated with long-distance transportation. However, it is important to consider the environmental impact of the materials used for 3D printing and their disposal at the end of the product lifecycle.

Looking ahead, the future of 3D printing holds tremendous potential. Ongoing research and development efforts are focused on expanding the capabilities and applications of this technology. Innovations in material development, such as conductive and bioactive materials, are opening up new possibilities in fields like electronics and healthcare. Advancements in printer technology, including faster printing speeds, larger build volumes, and higher resolution, are making 3D printing more accessible and efficient for a wider range of users. Moreover, the integration of 3D printing with other cutting-edge technologies, such as robotics and artificial intelligence, presents opportunities for automation, customization, and even more intricate designs.

In conclusion, 3D printing has emerged as a transformative technology with the potential to reshape manufacturing processes across various industries. Its principles, processes, materials, and applications have proven to be versatile and impactful. While it comes with its own set of limitations and challenges, ongoing research and development are constantly pushing the boundaries of what 3D printing can achieve. As the technology continues to evolve, it will likely have a profound impact on industries, supply chains, intellectual property rights, environmental sustainability, and the very nature of how we manufacture and consume products.